Many may be familiar with the name Marc Newson, an Australian born, world-renowned industrial designer. As one of the most acclaimed and influential designers of his generation, and hailed one of the world’s 100 most influential people by Time Magazine, Marc Newson was the perfect designer to work in collaboration with Noritake to create a new sense of style in tableware.

Originally designed for Qantas International First and Business Class cabins, this beautiful bone china collection features Newson’s signature sleek and fluid design. The simplicity and stunning contemporary design may bring many to believe that the process of design and manufacturing for this collection was an easy one. However in reality the immense effort and trial and error placed into creating each piece is difficult to believe, and truly redefines the impossible.

Newson’s vision for aesthetic beauty in his designs did not consider the difficulties in manufacturing tableware. His vision was to create a new style of dinnerware, where the main element was for the dinnerware to be made to visually look as if it were floating in space. This required the foot at the base of the tableware to be made as unobtrusive as possible. The foot’s height was made as short, and the size of the circle was made as small as possible. If the foot’s circle was too small, the tableware could not be stable. After a long period of going back to the drawing board, the Marc Newson collection achieved the perfect balance. Looking from a diagonal-top view, the collection has a sense of floating in space.

Furthermore, Newson designed the plates to have the edges as flat as possible, with a perpendicular edge to the plate’s flat rim. Considering the elements of strength and chipping, this was another difficult design, especially when the tableware was to be used during flights. The end design was a flat surface that rises only half an inch from the edge.

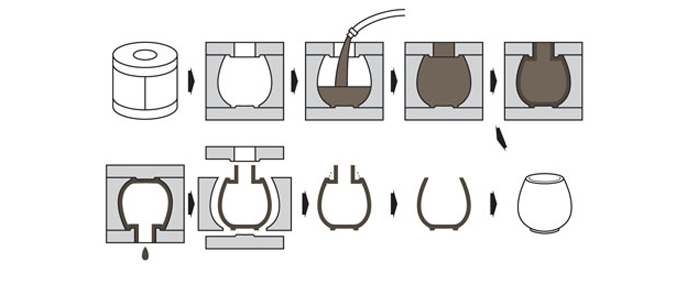

One of the most difficult manufacturing aspects was Newson’s signature design style shown through his design of the cups and mugs, where the diameter of the top of the cup was increasingly narrow from the bottom of the cup. This design was impossible to create using a traditional jiggering machine (an automatic machine based on a traditional potter’s wheel), as it only produces a wider top. A method was designed by Noritake using a plaster mould that is filled with liquid clay. The plaster absorbs the moisture, causing hardening of the interior walls of the clay, after which the liquid remains are taken out. When the mould is opened, the cup has been created. The work and costs required for this production method are much higher than the traditional methods.

It is astonishing how Newson’s designs and vision for this collection came to life, creating a new benchmark in dining where the combination of stunning contemporary design and brilliant functionality have not been substituted for diminished quality. All items in Marc Newson by Noritake Collection have been manufactured by Noritake to the highest standards from the finest bone china and are commercial quality tough, dishwasher and microwave safe.

Blog by Andrea Tang